What Does Dimensions Stand For in Robotics Engineering: Essential Concepts Explained

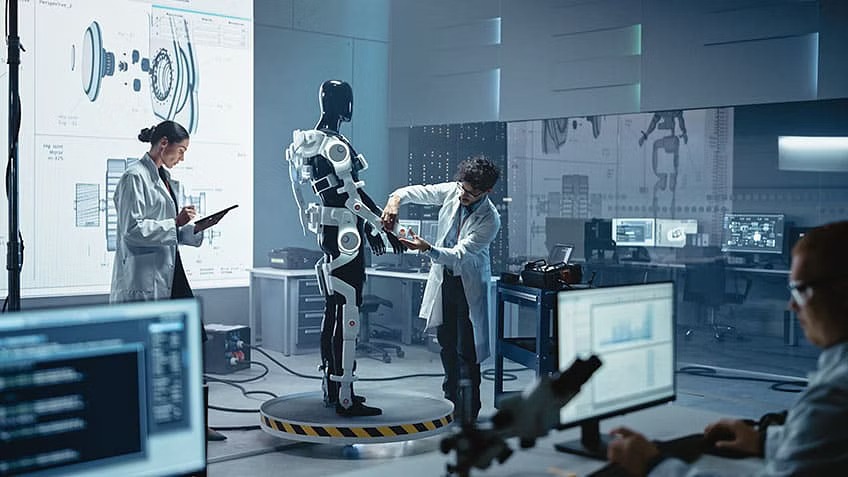

In the rapidly evolving field of robotics engineering, dimensions play a crucial role in determining how robots function, interact with their environment, and perform assigned tasks. Understanding what dimensions stand for in robotics engineering is fundamental for anyone looking to design, build, or work with robotic systems.

The Fundamental Concept of Dimensions in Robotics

When we talk about what does dimensions stand for in robotics engineering, we’re referring to several interconnected concepts that define a robot’s physical and operational characteristics. These dimensions aren’t just about size—they encompass a robot’s entire spatial and functional existence.

Physical Dimensions

At the most basic level, dimensions in robotics refer to the physical measurements of a robot:

- Length, width, and height – The basic spatial requirements

- Weight and mass distribution – Critical for balance and mobility

- Form factor – The overall shape that determines how a robot fits into its working environment

Degrees of Freedom: The Operational Dimensions

One of the most important aspects of what does dimensions stand for in robotics engineering is the concept of degrees of freedom (DOF).

What Are Degrees of Freedom?

Degrees of freedom represent the number of independent parameters that define a robot’s position and orientation in space. Each degree of freedom corresponds to a single independent motion that the robot can perform.

| Robot Type | Typical DOF | Examples |

|---|---|---|

| Industrial arms | 4-7 | Welding robots, assembly robots |

| Mobile robots | 2-3 | Warehouse robots, vacuum cleaners |

| Humanoid robots | 20+ | Research platforms, service robots |

Why DOF Matters in Robotics

The number of degrees of freedom directly impacts:

- Dexterity – How precisely a robot can manipulate objects

- Workspace – The total volume a robot can reach

- Complexity – The control systems required to manage movement

Workspace Dimensions in Robotics Engineering

Another critical aspect of what does dimensions stand for in robotics engineering is the workspace—the total volume within which a robot can operate.

Types of Workspaces

Robotics engineers consider several workspaces when designing systems:

- Reachable workspace – All points the robot can reach in at least one orientation

- Dexterous workspace – Points the robot can reach in multiple orientations

- Usable workspace – The practical working area considering obstacles and restrictions

Dimensional Analysis in Robot Design

When robotics engineers design new systems, they must conduct thorough dimensional analysis to ensure optimal performance.

The GMRU Approach to Dimensional Engineering

Professional robotics firms often use specialized simulation tools to model and optimize robot dimensions before physical prototyping begins read at GMRU.co.uk.

Key Considerations in Dimensional Analysis

- Kinematic reach – Ensuring the robot can access all required points

- Payload capacity – Designing dimensions to support required lifting capabilities

- Precision requirements – Scaling dimensions to achieve needed accuracy

Dimensional Scaling in Micro and Macro Robotics

What does dimensions stand for in robotics engineering changes dramatically when we move across different scales of robotics.

Micro-Robotics Dimensional Challenges

At the microscale, dimensions face unique constraints:

- Surface forces dominate over gravitational forces

- Thermal effects become more significant

- Manufacturing precision becomes extremely challenging

Macro-Robotics Dimensional Considerations

For large-scale robots, different dimensional challenges emerge:

- Structural integrity becomes paramount

- Power requirements scale non-linearly

- Safety zones must be larger

Time as the Fourth Dimension in Robotics

While we typically think of dimensions in spatial terms, time serves as a critical fourth dimension in robotics engineering.

Temporal Dimensions in Robot Operation

- Cycle time – How quickly a robot can complete a task

- Response time – How fast a robot reacts to inputs

- Service life – The operational timespan of components

Virtual Dimensions in Modern Robotics

As robotics becomes increasingly integrated with digital systems, virtual dimensions have emerged as an important concept.

Digital Twins and Virtual Dimensions

Modern robots often maintain a virtual representation—or digital twin—that mirrors their physical state and dimensions in real-time.

Augmented Reality Applications

Robotics engineers now use augmented reality to visualize and manipulate robot dimensions during:

- Design phases – Testing dimensional configurations virtually

- Maintenance procedures – Guiding technicians through complex geometries

- Training scenarios – Teaching operators about dimensional constraints

Standardized Dimensional Systems in Robotics

To ensure interoperability, the robotics industry has developed several standardized dimensional systems.

Common Dimensional Standards

- ISO standards for industrial robots

- JAUS (Joint Architecture for Unmanned Systems) for military and security robots

- ROS (Robot Operating System) dimensional parameters for research robots

Dimensions and Robot Navigation

For mobile robots, dimensions play a crucial role in navigation and path planning.

How Dimensions Affect Navigation

- Footprint considerations – The 2D projection of the robot that must be considered for collision avoidance

- Turning radius – Determined by the robot’s dimensions and wheel configuration

- Height clearance – Critical for environments with overhead obstacles

Human-Robot Interaction Dimensions

When robots work alongside humans, dimensions take on new importance in terms of safety and usability.

Anthropomorphic Dimensions

Many collaborative robots are designed with dimensions that mimic human proportions to create intuitive interactions.

Safety Dimension Requirements

Collaborative robots must maintain:

- Speed limitations based on proximity to humans

- Force limitations to prevent injury

- Reaction dimensions – How quickly and how far a robot can move in emergency situations

Conclusion

What does dimensions stand for in robotics engineering encompasses far more than simple physical measurements. Dimensions in robotics represent a complex interplay of spatial, temporal, operational, and even virtual characteristics that define how robots function and interact with their environment.

As robotics technology continues to advance, dimensional considerations will only become more sophisticated, integrating new sensors, materials, and artificial intelligence to create robots that can operate with increasing versatility and precision in diverse environments.

Understanding the multifaceted nature of dimensions in robotics engineering is essential for anyone working in this exciting field, whether designing new systems, implementing existing ones, or researching future robotics technologies.